PRODEVCO PCR42

Plasma Cutters

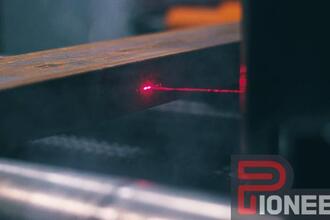

The PCR42 is our advanced robotic plasma steel cutting solution that combines CNC plasma cutting and torch technology with fully-automated robotics and laser measuring systems along with 7-axis motion that allows the cutting head to reach the bottom of all 4 faces of the profiles. Reduce layout and layout errors with the Scribing and layout features. The Interface uses DSTV (NC1) files and accepts files directly from 3d Detailing software. Solidworks, Inventor, Tekla and SDS2.

Processing Material Types

Types: S-Shape, W-Shape, HP-Shape, C-Shape, MC-Shape, L-Shape, ST-Shape, P-Shape, M-Shape, PL-Shape, HSS-Rectangle & HSS-Square

Up to 10x Productivity Increase

7-Axis Operations

Small Footprint & Flexible Layout

Hypertherm XPR 300 can pierce up to 1-3/4” and edge start 3”

Includes training, software, warranty, and Support.

| Cut-Width | 36" |

| Cut-Length | 0" |

| Plasma Power | 0 a |

| # Plasma Torches | 1 |

| Control | CNC |

| Dimensions | 12' x 12' x 11' |

| Weight | 6500 lbs |

Shapes Processed

H beam

Width 4"-40"

Height 4"-16"

Channel

Width 3"-40"

Height 1-1/4- 16"

Angle

Width 2"-8"

Height 2"-20"

HSS

4"-26"

Hypertherm XPR 300

Pierce 1-3/4

Edge Start 3"

Data Sources

TEKLA, SDS/2,Graitec and other detailing software

Hypertherm XPR300 power supply

Fanuc Robot

Sizes: I- Beam up to 48"

HSS REctangle up to 20"x24"

Pierce up to 1-3/4" a

Edge Start 3"

Fanuc Robot

Hypertherm XPR 300 Plasma

3D Laser System measuring

40' infeed and 40' outfeed conveyors

Enclosed work area

Dust Collection

3D programing software