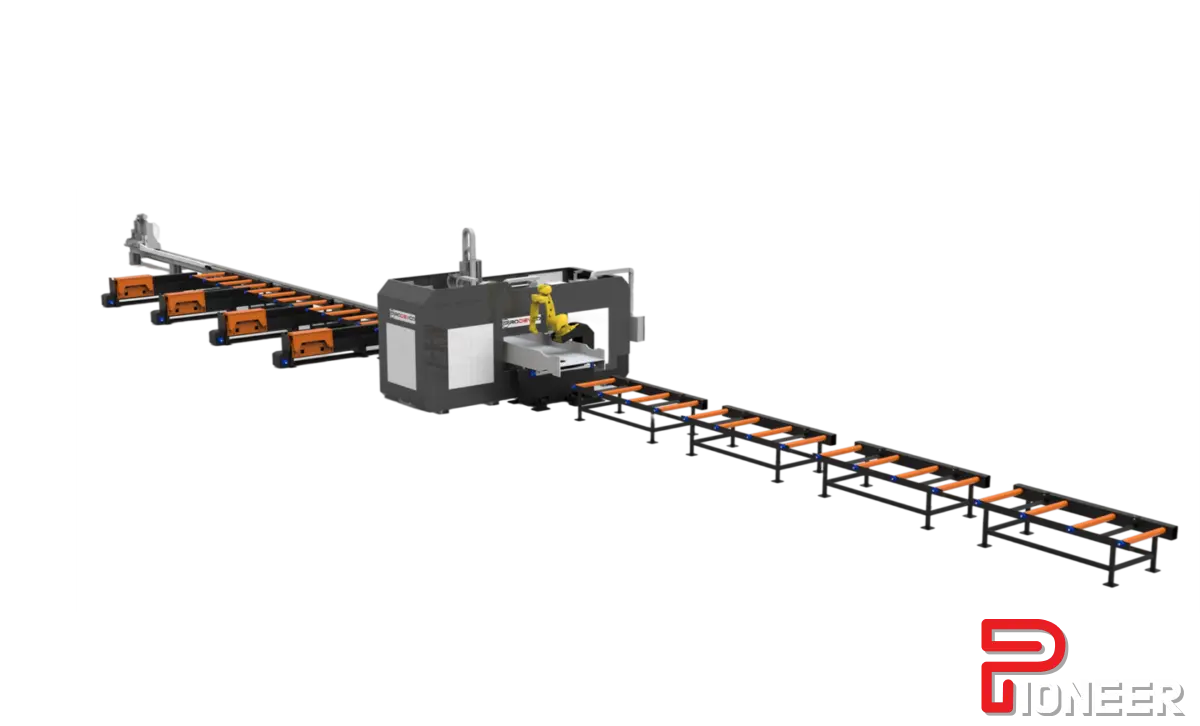

Our advanced, dual-function machine combining both drilling and plasma cutting capabilities into one system

Key features/advantages include:

• Sub-Axis spindle positioning allows simultaneous drilling on all 3 faces even when holes are not aligned, as well as machining for slots

• Capable carbide marking and scribing

• Automatic tool changer with up to 3 tool positions per side for various tasks such as drilling, milling, tapping, countersinking, layout marking and centerpoint marking

• Pincher with rack and pinion positioning and measuring to achieve the highest accuracy

• Operator control from touchscreen with industrial PC, utilizing our simple-to-use in-house software that processes industry-standard DSTV (.NC1) files seamlessly

Section Size (Min): 6″x 3″ (150x75mm)

Section Size (Max): 51″x 24″ (1300x600mm)

Drilling Head (No.): 3

Drill Bit Capacity Ø: 1/2″ to 1-1/2″ (12 to 40mm)

Automatic Tool Changer Option: 3 set per axis

Spindle Power: 24 HP (18kw)

Spindle Sub Axis Stroke: 17″ (430mm)

Double Miter Plasma Cutting: -45°, +65°

Plasma Cutting Hypertherm: XPR300

Plasma Pierce Capacity: 1 3/4″ – 2″ argon assist

We use cookies to improve your experience. Privacy Policy.