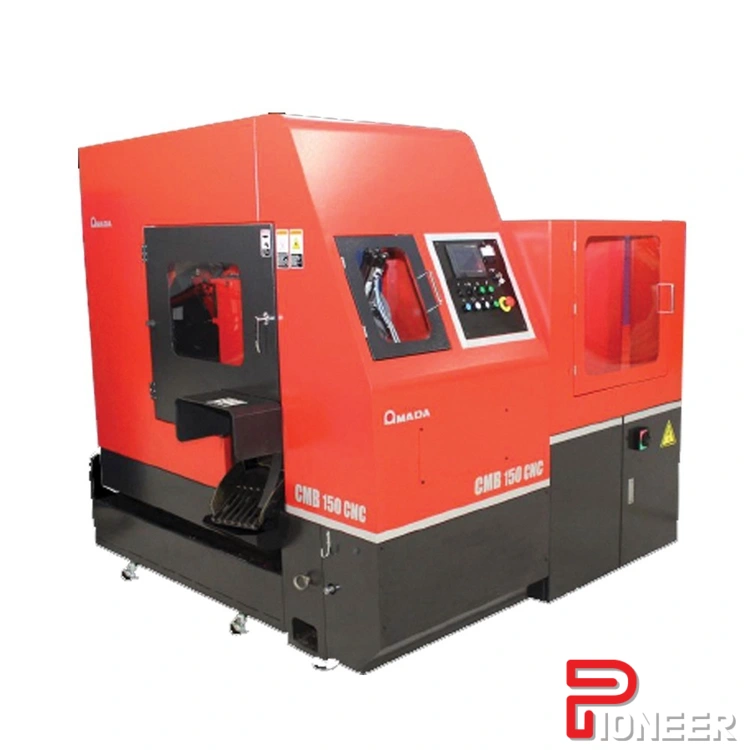

High Precision Cutting with Short Cycle Times

• 15 H.P.

• Incline Table

• Chip Conveyor

• Cut Piece Counter

• Anti-Backlash Device

• Sorting Device

FEATURES

• High-Speed, High-Precision Cutting

- Parts are cut using an oblique-slide cutting mechanism. This ensures high precision positioning to +/- 0.01mm and an optimal rake angle for cutting bar steel. This design improves stability, resulting in higher precision and enhanced cutting rates.

• AMADA MACHINERY’S Unique Carbide Tipped Tool

- The saw blade is a very important factor in realizing high speed, high precision cutting. Amada has developed a unique carbide-tipped circular saw that cuts cleanly and virtually burr-free.

• Capable of Cutting a Variety of Metal Materials

- This machine can cut a wide variety of materials including round bar and flat bar in a range of materials like mild steel, stainless steel, tools steels, and nonferrous materials.

• Spray-mist Lubricant Reduces Cutting Fluid Cleanup

- This machine incorporates a semi-dry cut system that generates eco-friendly oil mist, thus work pieces get less wet while cutting; resulting in simplified downstream processes.

• No Clean-Up Process Needed for the Cut-Face

- This machine makes highly precise cuts, the resulting cut-face being very clean. By eliminating the surfacing work, like when materials are band saw cut, the total processing time is greatly reduced.

• Longer Circular Saw Blade Life

- Using an oblique-slide (from the upper oblique direction) cutting mechanism and cermet carbide pads, which dampen most vibrations that result from cutting, lessens the wear of the sal blade. Resulting in a much greater service life of the circular blades and noticeably reducing the costs/cut.

Cutting Capacity:

Round (Diameter) 2.95″-6.0″ 75-152.4 mm

Rectangle (W x H) 2.95″ x 2.95″ – 3.94″ x 3.94″ 75 x 75 – 100 x 100 mm

Maximum Stock Table Loading Capacity, Round Bars (L x D):

19.7′ x 6.0″ x 3 bars or 5,732 lbs* 6000 x 152.4 mm x 3 bars or 2600 kg*

Incline Table Dimensions (L x W x H)

17.8′ x 46.9″ x 44.0″ 5431 x 1190 x 1117 mm

Saw Blade:

Number of Teeth

OD x Bore x T 18.1″ x 1.97″ x 0.11″ 460 x 50 x 2.7 mm

Blade Speed 39-149 RPM by Inverter

Motors:

Saw Blade 15 HP 11 kW

Saw Head Feed 2.75 HP Servo Motor 2.0 kW Servo Motor

Hydraulic Pump 2 HP 1.5 kW

Cut-to-Length Feed 3/4 HP Servo Motor 0.5 kW Servo Motor

Power Requirement:

Power Supply Voltage AC220V±10%, 3 PH, 60 Hz

All Other Voltages Require Transformer

Power Requirement 32.5 kVA

Hydraulic Tank Capacity 5.3 gal 20 L

Material Index:

Index Mechanism Shuttle Vise

Material Index AC Servo Motor & Ball Screw

Stroke 0.2″-29.7″ 5-755 mm

Length 0.78″-472.44″ Multiple Indexing 20-12000.0 mm Multiple Indexing

End Trimming Length 0.78″-3.9″ 20-99 mm

Remnant Length 3.54″-3.54″ Plus Length of Parts 90-90 mm Plus Length of Parts

Machine Dimensions (W x L x H)

85.1″ x 77.4″ x 74.1″ 2160 x 1967 x 1882 mm

Table Height 31.5″ 800 mm

Machine Weight 6.613 lbs 3,000 kg

*1: Evenly Distributed Over Entire Table

We use cookies to improve your experience. Privacy Policy.