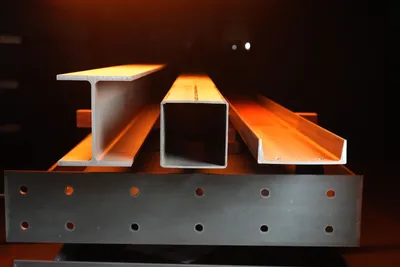

Introducing the new AGT Robotics BeamMaster Robotic Welding System. Offering precision with joint detection via SnapCam, flexible MCAW/GMAW processes, and superior fillet weld speed. Achieve optimal results with Hobart or Lincoln wires. Ideal for clean surfaces.

Imperial / Metric

Fence to Fence: 112′ / 34.1 m

EWZ 1: 40′ / 12 m

EWZ 2: 40′ / 12 m

EWZ 1 & 2: 92′ / 29 m

Height: 13′ / 3.95 m

WELDING SPECIFICATIONS

Fillet welds (2f) – travel speed

• 3/16″ weld: 20.0 in/min (8.4 mm/s)

• 1/4″ weld: 15.0 in/min (6.4 mm/s)

• 5/16″ weld: 10.0 in/min (4.6 mm/s)

Speed may be increased if fit-up allows.

Gap detection: No gap detection

Joint detection: 3-D camera point-cloud seam finding (SnapCam)

Process & position

• MCAW – spray & pulse transfer modes / BS EN ISO 4063 Process 138

• GMAW – spray & pulse transfer modes / BS EN ISO 4063 Process 135

Welding wire

• MCAW: AWS A5.18 / A5.18M E70C-6M H4 | CSA W48-06 E491C-6MJ-H4

• GMAW: AWS A5.18 / A5.18M ER70S-6 | CSA W48-06 B-G 49A 3 C1 S6

Approved filler metals

Preferred – MCAW: Hobart Fabcor Edge 0.045″ (1.2 mm)

Alternative – GMAW: Lincoln SuperArc L-59 0.045″ (1.2 mm)

Shielding gas

• 85 % Ar / 15 % CO₂ (M20)

• 90 % Ar / 10 % CO₂ (M20)

Surface finish

All parts and beams must be clean, with no excessive rust or mill scale.

Procedures exist for both sand-blasted surfaces and mill scale; highest quality is obtained on sand-blasted surfaces, while mill-scale surfaces require slower welding speeds.

We use cookies to improve your experience. Privacy Policy.